Peak Season: Curse or Blessing?

Market Monday - Week 49 - Turning European Market Seasonality to Your Advantage

If you’ve followed recent developments, you’ve likely noticed that European road freight is looking a little different these days. With capacity tightening down and rates decoupling from their usual patterns, the traditional shipper-power approach to annual tenders is becoming less bulletproof. In today’s volatile market and always-rising costs situation, few carriers will risk squeezing themselves out to get that lucrative annual volume figure. And shippers trusting those few that take the risks often face rejections and rate increase inquiries very soon.

But volatility isn’t necessarily a bad thing. In fact, for large FTL shippers, market fluctuation might be a solvable puzzle. The secret isn’t just finding the lowest rate; it’s about matching your procurement strategy to the market’s rhythm.

Let’s start with the non-negotiables. Your “must do” might be the Q4 retail rush or the pre-summer industrial push—where failing to deliver is not an option. During these high-season peaks, the data shows that carrier rejection rates on standard contracts often spike as they chase higher yields in the spot market. If you absolutely need to move goods during these windows, the strategy is simple: prioritise security over savings.

This is the time for “ironclad” contracts. You might pay a premium or agree to pay for space even if you don’t use it, but you are buying for certainty. To further secure this capacity, consider optional indexing of your contracts based on neutral data, such as Transporeon Market Insights. Allowing rates to flex with market reality removes the incentive for carriers to reject your loads, ensuring the freight moves even during capacity shortages. Having guaranteed delivery often is worth more than a theoretically low rate that never shows up.

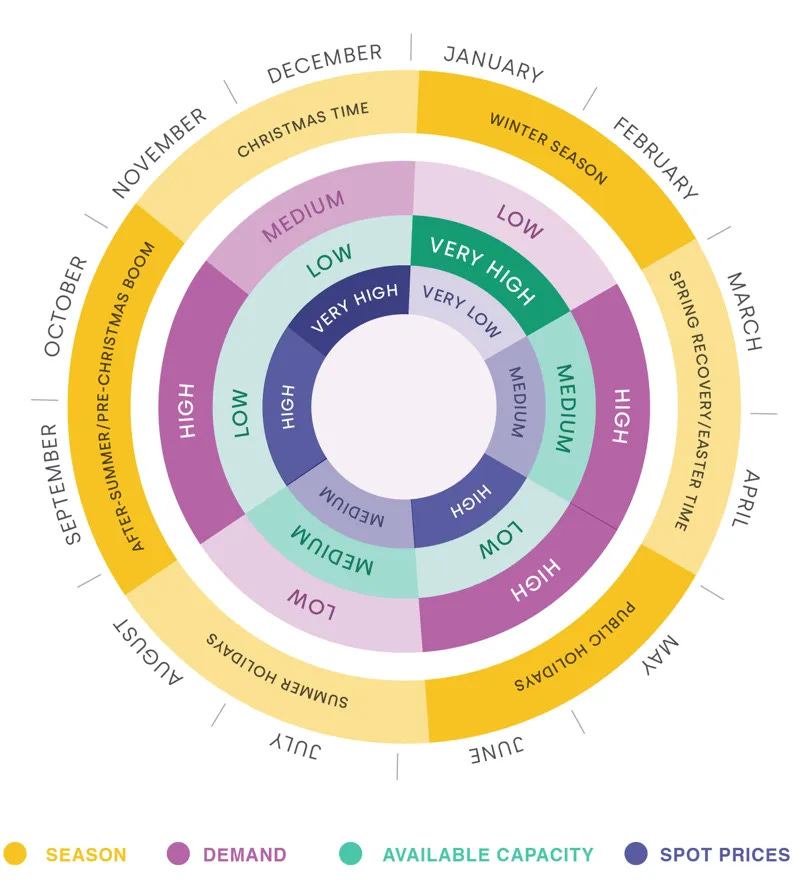

The infographic below illustrates in detail how different seasons typically influence the market in general:

Source: Transporeon

However, seasonality is rarely a two-way street. Often, the market moves in a massive “head haul” wave—think of agricultural goods moving South to North or retail goods moving from import and distribution hubs to consumers.

If you are lucky enough to need shipping in the opposite direction of the crowd, you have a huge advantage. Carriers dropping off high-paying loads are often eager to get their trucks back without running empty. In these seasonal scenarios, locking in a fixed annual contract may be detrimental to you. Instead, try leveraging the spot market for these specific lanes. You’ll often find carriers willing to move your freight for little more than the cost of fuel and tolls during the high season in the opposite direction, just to reposition their fleet. Being flexible in how you buy can be as important as what you buy.

Another underutilised lever for shippers could be simply changing when you ship. If your goods aren’t perishable and your storage costs are manageable, either smoothing out your volume to avoid capacity issues or shifting it to the low season can lead to massive savings, because carriers hate volatility in capacity as much as you do. They have trucks to use and drivers that need to be paid each month.

Consider approaching your core carriers on existing lanes with a strategic offer: dedicate significantly larger allocations to them specifically during the off-season. By keeping their wheels turning when the rest of the market goes quiet, you can solve a major utilisation problem for them. In exchange, you can negotiate discounts that apply within the year, lowering your overall annual spend.

When carriers aren’t sure if your projected yearly volume is real, they bake a “risk premium” into your price. You can strip that premium away by sharing your seasonal forecasts transparently. Don’t just give them a rough estimate - show the schedules. Demonstrating a solid off-peak volume allows carriers to plan with confidence. When they know the freight will be there, they don’t need to hedge their bets with higher prices.

To achieve a win-win situation, shippers should not be the only ones with a stick; instead, they should be flexible with procurement strategies across all lanes. The winners will be those who surf the seasonal waves and work with their logistics service partners, rather than trying to swim against the current.

Oleksandr Kulish

Senior Consultant